Molsheim, 03/2024

MBTM has recently embarked on an ambitious project aimed at digitizing plans and manufacturing ranges in the commercial vehicle transformation sector. This initiative signifies a major shift towards digitalizing our operational processes.

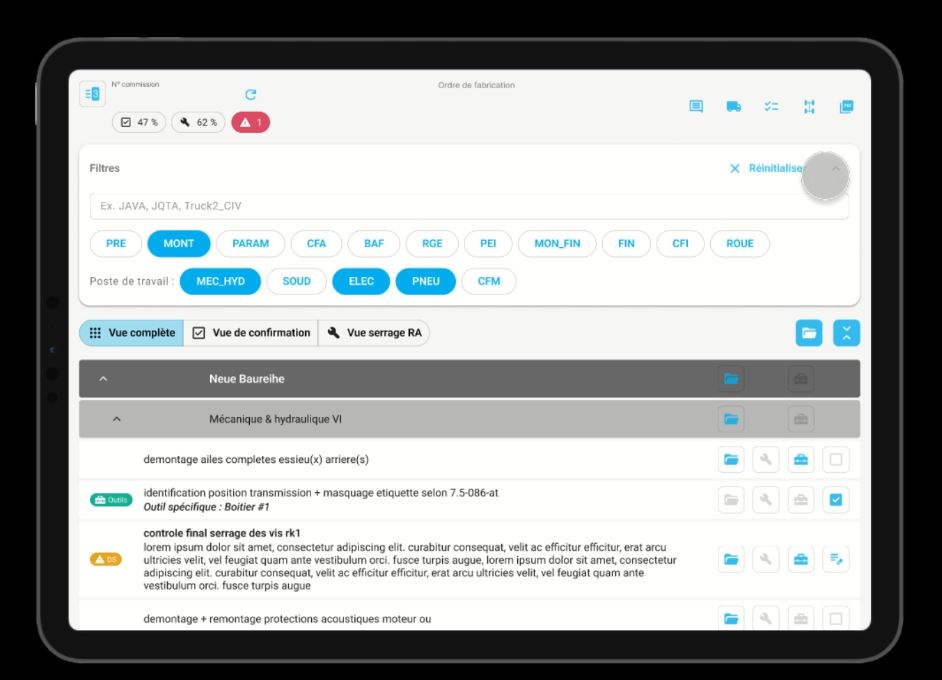

A pilot phase is currently underway in one of our workshops, necessitating close collaboration between production operators and various support services such as methods and engineering.

The objective of this phase is to create 3D plans of the entire truck and associated transformations, replacing traditional paper plans. Concurrently, the digitization process of manufacturing ranges is also under development.

Key objectives include:

- Drastically reducing our paper consumption, thereby contributing to our environmental sustainability efforts. The annual savings will amount to approximately 200,000 sheets for paper!

- Optimizing the time required to search information in assembly ranges and plans, thereby enhancing the overall efficiency of our production processes.

- Increasing the traceability of work performed on the truck.

The pilot phase will gradually extend to other vehicle transformation workshops through 2024, with full implementation slated for 2025. The project will then be rolled out to parts production workshops.

This initiative represents a significant advancement for MBTM, showcasing our commitment to innovation and continuous improvement. We are confident that this transition to digitalization will bolster our competitiveness and market position, while also fostering a more efficient and sustainable work environment.